Monday, July 29, 2013

How It's Made Steel Forgings

The jokes just never stop coming from How It's Made. Their opening jokes are as corny as Kansas in August.

Our Tuscaloosa camp got to see an electric arc furnace at work at Nucor Steel. If ever you get the chance, do not miss seeing one of those at work. They're stunning and absolutely awesome.

The glowing blocks at 2:45 would be amazing to see in person, as would the forging press at 3:00. Wow...

How honeycombs can build themselves

|

| Image source - http://www.huffingtonpost.com/2013/07/17/honeycombs-build-themselves-physics-bees_n_3611825.html |

Apparently in this case physics beats biology...

Karihaloo and his colleagues seem to have clinched this argument with their study. The team interrupted honeybees making a comb by smoking them out of the hive, and found that the most recently built cells have a circular shape, whereas those just a little older have developed into hexagons. The authors say that the worker bees that make the comb knead and heat the wax with their bodies until it reaches about 45 oC — warm enough to flow like a viscous liquid.Stupid physics...

2012 Eisenman Materials Camp Lab

This video - published on ASM's YouTube channel - takes a quick tour of the Eisenman Materials Science camp, ASM's longest ongoing summer student camp. Since this camp was first run more than a decade ago now, the program has expanded to more than twenty-five student camp around the country.

The camps are largely run by volunteers and see the students broken up into five- and six-student teams who then work on a single project for the week under the supervision of an industry mentor/expert. It makes for a spectacular introduction to the world of materials science for the students who get to attend.

Check out the full camp schedule and start thinking about which of your students should be attending these entirely free camps.

ASM Materials Camp 2012

I kinda wish I would've gotten to go to an ASM materials camp when I was a high school student. I'm thinking that if I had, I might've ended up heading down a different path.

Not that I don't love my job now. I do love it. Especially if my principal happens to stumble upon this blog. I love my job and my boss.

This video gives a glimpse into the week-long student summer materials camps. In the camps the students are broken into small (five- or six-student) groups and spend the week exploring an group-specific problem. Along the way, the whole group comes together for some materials instruction and a few activities - like the forging going on under the tent above. It's a very different set-up from the teacher camps and one that lets the students be even more hands on.

The above video captures some highlights from and interviews at the Eisenman Materials Science camp that takes place each summer at the ASM headquarters in Materials Park, OH - one of more than twenty student camps each summer. Check out the full camp schedule on the ASM foundation website.

Training Camp for Science Teachers

|

| Image source - http://cen.acs.org/articles/91/i21/Training-Camp-Science-Teachers.html |

I am particularly happy about the last few paragraphs...

ASM’s data show that of the roughly 4,000 “graduates” over the past 10 years, about 60% of whom teach high school chemistry, more than 80% incorporate some of the camp activities into their teaching.Thanks for the good coverage, Mitch

Marilyn Weiss, who teaches Advanced Placement and other chemistry classes at Park Tudor Upper School in Indianapolis, says she includes many of the lessons she learned at the camp last summer. Examples include exercises on metal plating and electrochemistry, as well as experiments on the properties of metals and alloys and physical differences between two polymers.

In addition to picking up valuable teaching techniques, Tracy Schloemer, a 10th-grade chemistry teacher at Denver School of Science & Technology, says she made great contacts at the camp last summer. “As a teacher, I find networking can be tough. The ASM camp enabled me to meet a diverse crowd of teachers and academic faculty.” Schloemer gives the camp a thumbs-up and is quick to recommend it to colleagues. “It’s free, and you get plenty of stuff to use in the classroom. Why wouldn’t you want to go?”

Sunday, July 28, 2013

One order of steel; hold the greenhouse gases

|

| Image source - http://www.petrodrillingtools.com/factory.asp?bigclassname=factory&smallclassname=Steel-making |

I don't mean to say that the plant tour was bad or unpleasant, it was far from those. Instead, it was one of the most fascinating industrial settings that I have ever, ever seen. Instead, the heat and fire and sparks and glowing light could only be analogous to our cultural images of eternal damnation in hellfire.

...and it's apparently bad for our environment, something else I got to see in Provo, Utah, when I saw the remnants of Geneva Steel, a cleanup that has been ongoing for more than twenty years.

But I digress...

Today's article - from the MIT website - reports on a paper in the journal Nature titled "A new anode material for oxygen evolution in molten oxide electrolysis". The paper describes a new process of steel making that promises to produce higher quality steel at a cheaper cost and with less carbon dioxide production. Instead of using a carbon to chemically reduce iron ore (producing carbon dioxide as greenhouse-effect-worsening byproduct), the described process initially used an iridium anode but finally settled on a chromium/iron alloy which is, according to researcher Donald Sadoway, is "abundant and cheap."

The connections to our summer workshop are all over the place...

- oxidation happening more quickly at high temperatures ("about 1600 degrees Celsius")

- chemical reduction via the activity series (carbon used to reduce iron oxides)

- electrolytic reduction at the anode

- protective oxide coatings (like aluminum's) on the iron/chromium alloy anode

- ceramics and some metals having much higher melting points than others

- interdisciplinary approach to science ("Electrochemistry is a multidisciplinary problem, involving chemical, electrical[,] and materials engineering.")

How It's Made - Fiber Cement Siding

I can say that I am a homeowner of a home covered in fiber cement board, specifically HardiePanels.

At 1:03 the video says that water is pumped into the pulverized sand to 'liquify' the sand. Really? In my head, liquify means melting. The sand clearly isn't melting, but it is coming together into a slurry. Is the word liquify being used correctly there?

Production of the cement fiber boards here are conceptually simple - sand, cement, wood fiber, water - but impressively complex in processing, particularly the use of pressurized steam to speed up the cement curing process.

What Stresses Gorilla Glass Makes It Stronger

|

| Image source - http://www.connectedrogers.ca/news/ask-an-expert-gorilla-glass/ |

I appreciate the comment in the summary article from InsideScience.org that states that

Voigtmann and his coauthors describe glass's residual stress in physics terms, by observing how the motion of individual atoms affects the entire complex system. But engineers are already taking advantage of glass's history dependence—no theoretical physics required.The article goes on to explain the process of producing Gorilla Glass - hardening in a bath of molten potassium salts - and why this produces a remarkably hard, durable glass.

ASM International Headquarters Renovation Projects

This video - only 1:39 long - shows a slide show of the background and accomplishments involved in the renovation of the ASM headquarters in Materials Park, OH. I'll readily admit that I absolutely love getting to visit the ASM headquarters each year for our master teacher training in April.

If you're a member of ASM, make sure to stop by if you're ever in the Cleveland area.

ASM International Headquarters

ASM's headquarters in Materials Park, OH, was built in 1959 as a cutting-edge architectural marvel. This video does a great job recapping a very quick history of the building and some of the renovations that were necessary by the turn of the century.

Princeton materials Science Camp for Teachers

That's a pretty fair description of the ASM summer camp from Dan Steinberg...

This is a five-day, intensive camp to teach materials science to materials science teacher taught by master teachers and Princeton professors.Brian Wright, seen at 0:25 and again at 0:49, has been teaching the Princeton camp for a number of years. It's great to see an ASM volunteer, a Princeton professor, and a whole lot of excited teacher campers.

This video is a well-produced, fairly slick promo video about the Princeton summer ASM camp.

Wednesday, July 24, 2013

How It's Made Hammers

"No one-hit wonder"...funny stuff here...

I love the simplicity - in general appearance, anyway - of forging...and the fire that flares from the oil quenching at 2:20...

Ok, in reality, these look like really nice hammers, especially the ones with the resin-dipped leather handles.

"They've really nailed it"...still funny...

Anybody know who writes these How It's Made scripts?

Clips from PCCM's 1st Materials Camp for Teachers

I wish I had one of those maroon polo shirts. In our program the number of different color polo shirts is a little bit of a badge of honor. The more colors, the longer a teacher has been part of the program. I'll admit to having a geeky pleasure when I could go a full five days without repeating any colors this summer. Take that, Becky!

This isn't any sort of finished product. It's a bunch of barely edited clips from PCCM's - Princeton Center for Complex Materials - first ever summer materials science camp for teachers, probably from 2004. Most of the clips are of camper teachers giving remarks toward the end of the camp.

It's interesting to see some of the older ways that we did the labs - piling cement blocks on the concrete bars for destructive testing. Through the years the labs have certainly been refined, as has the whole curriculum.

It's good to hear many of the same compliments from the camper teachers that we still hear - that applied knowledge is more important than theory without application, the materials for the activities are cheap, demonstrations with explanations are powerful, the information is relateable for both upper- and lower-level students, and that the summer workshop is the best workshop they'd ever been to.

Mississippi Mornings #2 6-10-2013

Good morning!

Friday at Meridian High School was apparently a little crowded as this is the second report broadcast and recorded while the campers were measuring Young's modulus.

Great job from camper Perry Buxton reminding us that students need to do things instead of just practicing for the state tests.

Teachers Using Everyday Objects to Teach

It's always good to get a some good press for the local teachers and organizers of one of our ASM summer teacher camps. It's not always as much fun to be asked to explain the camp to reporters in a few soundbites.

Todd, however, did a nice job when the Meridian press stopped by on Friday during the June 2013 teachers camp at Meridian High School in Meridian, MS to put together the above report, interviewing one camper and one master teacher and showing the campers measuring Young's modulus on composite day.

In a neat turn, the camp didn't have any spot plates for the bismuth-tin alloy lab (to demonstrate the eutectic point). The master teachers improvised and finally landed on the solution shown at 1:00 in the video: plaster of Paris molds using Whoppers for the forms. According to Caryn Jackson, they first tried glass beads (like those found in a Pente game) and grapes before settling on the Whoppers. Apparently the Whoppers also had the benefit of leaving a little wax/chocolate coating behind that seemed to ease the spots' journey out of the molds.

Nice save, Todd, Tom, and Caryn.

Teachers head back to school in Tuscaloosa

In June of 2013 channel 42 out of Birmingham, AL stopped by the University of Alabama's ASM summer teacher camp and produced the above video and this story for their newscast and website.

It's not a huge part, but it does show a quick glimpse of the campers doing NACE lab #2 - Mr. Copper and Miss Sulfate.

Having been in Alabama when this was filmed, I can successfully say that the campers did successfully develop the activity series.

Small in size, big on power: New microbatteries a boost for electronics

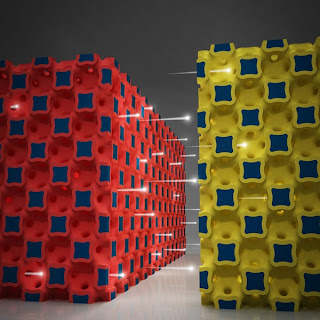

Either the Borg are about to assimilate that yellow cube, or we've got a new type of battery on our hands.

The article - from the University of Illinois's news bureau - summarizes research published in the April 16, 2013 issue of the journal Nature Communications under the far more technical title "[h]igh-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes".

To summarize (enough to whet your whistle)...

The article - from the University of Illinois's news bureau - summarizes research published in the April 16, 2013 issue of the journal Nature Communications under the far more technical title "[h]igh-power lithium ion microbatteries from interdigitated three-dimensional bicontinuous nanoporous electrodes".

To summarize (enough to whet your whistle)...

With currently available power sources, users have had to choose between power and energy. For applications that need a lot of power, like broadcasting a radio signal over a long distance, capacitors can release energy very quickly but can only store a small amount. For applications that need a lot of energy, like playing a radio for a long time, fuel cells and batteries can hold a lot of energy but release it or recharge slowly.Maybe supercapicitors aren't the answer after all...

The new microbatteries offer both power and energy, and by tweaking the structure a bit, the researchers can tune them over a wide range on the power-versus-energy scale.

The batteries owe their high performance to their internal three-dimensional microstructure. Batteries have two key components: the anode (minus side) and cathode (plus side). Building on a novel fast-charging cathode design by materials science and engineering professor Paul Braun’s group, King and Pikul developed a matching anode and then developed a new way to integrate the two components at the microscale to make a complete battery with superior performance.

Al 3anany Science Cement.flv

Wait, wait, wait - from 3:00 - "the powder goes into a preheater. The temperature of the powder is eighty degrees Celsius upon entering. Within forty seconds, it gets more than ten times hotter."

That's problematic to this old chemistry teacher. Does that mean it's up to 800 C (80 C x 10)? or 3530 K (353 K x 10)? If I've learned nothing else from the gas laws chapter, it's that if we're talking about doubling temperature, we'd better be talking about absolute temperature.

In spite of the atrocious largely gibberish title, this is a How It's Made video about cement. The video covers initial limestone blasting (open pit mining, I guess), rock crushing, mixing to reach the right proportion of calcium carbonate, bonding the minerals together and degassing (carbon dioxide release, anybody?) them via heat, and final grinding.

And then...and then...and then...

Sorry, the hypnotic motion of the grinding balls got me there for a second.

Where was I?

The Super Supercapacitor | Brian Golden Davis

The eureka moment described here feels a whole lot like the moment in Primer where Abe slides the car batteries out of the way. (What do you mean, you haven't seen Primer yet? Close this window and go watch it immediately.)

Batteries work...sort of...

Capacitors - specifically supercapicitors - may, however, just end up being a far more effective means of energy storage, something that we are desperately in need of as we make the - hopeful - shift from fossil fuels to renewables, some of which (solar, wind) are very much problematic in their ability to provide round the clock energy production.

Could capacitors be the solution?

Man invents machine to convert plastic into oil

This is our second video from the Our World series, exploring radical solutions to some of our greatest technological problems. Here we see a Japanese scientist who is looking to solve the problem of how to dispose of our huge amounts of petroleum-based, plastic trash.

I want to know what 'gas' he's speaking of at 2:00.

...and how long the processing of 1kg of plastic takes...

...how much energy has to be put into the machine to heat the plastic as compared to the energy density of the oil that comes out...

...if the process is scalable...

...why we aren't using this process already...

Tuesday, July 23, 2013

Nova: Secrets of the Samurai Sword

From tip to tail, this one's worth showing in full. I know I can't quite make it in one of our periods (48 minutes last year, no guess how long this year), but it would be well worth two days. Brilliant stuff combining art, science, history, so much. Wow.

New video posted as of 7/30/14 - All times should be modified by subtracting about 20 seconds. For example, 11:30 listed below is more like 11:10 in this video.

My highlights...

- 11:30 - switching from BCC to FCC iron, paralleling the iron wire demo and showing how steel forms from the iron

- 12:45 - Thoe Gray's tour of the periodic table (love his book, app, poster, all of it)

- 15:00 - Charpy hardness testing explanation - toughness vs hardness

- 22:00 - The breaking up of the furnace is just gorgeous to watch...brilliant and blinding and beautiful. Wow...

- 23:00-25:30 - Could be skipped if need be, compares Japanese samurai films to American westerns

- 31:10 - cold working, work hardening of copper and how that relates to crystal defects in the sword

- 33:30-36:00 - Also could be skipped as it doesn't cover any science, just showing us how impressive the swords and swordsmen are.

- 36:40 - Differences in types of steel - high- and low-carbon steel - and how they are combined to make a better sword

- 40:50 - Heat treating, quenching and what it does to high- and low-carbon steels

- 44:00 - Differential thermal expansion, like a bimetallic strip

- 45:30-47:00 - Skippable...how to use the sword properly in fighting

Real World: Space Shuttle Thermal Protection System

This video, produced by NASA, may not be quite as stunning as some of the other space shuttle tile videos, but it does a nice job explaining why the tiles are needed, how they're made, and what the other options are.

Oh, and I know my quote source here is Wikipedia, but I've read in a number of places that the explanation of friction being the cause of heating of the shuttle (and other objects) upon reentry to the atmosphere is incorrect. Rather, most of the heating is due to compression of the air.

Direct friction upon the reentry object is not the main cause of shock-layer heating. It is caused mainly from isentropic heating of the air molecules within the compression wave. Friction based entropy increases of the molecules within the wave also account for some heating....but Randall Munroe has my back, too...

Things get really hot when they come back from space. This isn’t because of air friction, strictly speaking—it’s because of air compression. The air can’t move out of the way fast enough, and gets squished in front of the spaceship/meteor/steak. Compressing air heats it up. As a rule of thumb, you start to notice compressive heating above about Mach 2 (which is why the Concorde had heat-resistant material on the leading edge of its wings).

Firing Raku Pottery in the Microwave Oven: The Paragon Kiln Operation Series

The Paragon Magic Fuse kiln is available online and from local dealers - there are four within twenty miles on my house. It's only $160 and weighs 5lbs, so I'm guessing the shipping wouldn't be too bad.

There are a few limitations of the kiln - the need for a microwave, the tiny maximum size of the piece being fired - but it is a way for you to do small raku projects without buying a larger kiln.

Plus it's just really frickin' cute!

Five High-Paying, Low-Stress Jobs

It doesn't get much more direct than Monster.com listing Materials Scientist as the #2 highest paying, lowest stress job out there right now.

2. Materials Scientist Median Annual Salary: $90,600That's the kind of fact that should be plastered on a t-shirt.

Synthetic fibers, lubricants, leak-proof materials -- these are a few of the products created by materials scientists. They need strong chemistry backgrounds and at least a bachelor’s degree to get started. Those holding a PhD often specialize in areas such as analytical chemistry or polymer chemistry.

Sunday, July 21, 2013

ASARCO - How It's Made: Copper

Aw, man...this video says it's 14:30 long, but the last five minutes is a repeat of the middle five minutes. The real video ends at 9:38.

Getting to that 9:38, though, is some impressive information about the mining and refining of copper.

Rock is exploded and strip mined...leached with sulfuric acid...electrochemically refined...or pulverized...turned into slurry and concentrated...mixed with silica flux and smelted...

The whole video is brilliantly informational, and the green flames - first appearing at 5:14 and reappearing a number of times, most brilliantly at 5:30 - are absolutely stunning.

Heck, the opportunity to see the shimmering, reflective, molten copper at 5:40 alone is worth the price of admission.

The video's original source is the ASARCO website...

http://www.asarco.com/about-us/our-locations/asarco-mineral-discovery-center/making-copper/

...and was uploaded to YouTube so it could be embedded here. The entirety of the ASARCO website has some great information about the copper refining process - images, diagrams, explanation, outstanding stuff. And, yes, the video is mirrored left-to-right, but the process is still shown clearly.

College Student Invents Building Material

It looks like Micah has taken down his blog - at least I can't find it via any of the search terms I could see at 1:39 in the video. He has, however, gone on to found Pulse Motors, an electric bicycle start-up - more about that here, here, and here.

It's always interesting in camp and in class to expand (see, I'm funny) on the uses of the expandable foam. There's the standard Great Stuff foam, expanding foam insulation, and Nerf, but what else is there to the foams?

Now there's making a building material out of them...in Pittsburgh, anyway.

Quick question, though, what's with the density currents above the container at 0:02 and again 4:55? Does the stuff cure faster with a heat gun treatment? Gotta try that sometime...

Pykrete - collecting videos

Pie-crete (sp?)...Mythbusters

In an earlier post, we saw a video go through the history of pykrete, a composite of wood pulp (or sawdust in some reports) and ice. The materials was championed by - and named for - a British inventor named Geoffrey Pyke.

When I brought up the material in class one year, a student mentioned that Mythbusters had done an episode on the feasibility of using pykrete as a boat-building material. Since I couldn't find the full episode online, I thought I'd post all the clips I could find - from Mythbusters and two other television shows exploring pykrete.

And I don't want to hear any snotty comments about Mythbusters.

In an earlier post, we saw a video go through the history of pykrete, a composite of wood pulp (or sawdust in some reports) and ice. The materials was championed by - and named for - a British inventor named Geoffrey Pyke.

When I brought up the material in class one year, a student mentioned that Mythbusters had done an episode on the feasibility of using pykrete as a boat-building material. Since I couldn't find the full episode online, I thought I'd post all the clips I could find - from Mythbusters and two other television shows exploring pykrete.

And I don't want to hear any snotty comments about Mythbusters.

Friday, July 12, 2013

Raku Pottery

I love watching potters work. Sure, just beat the snot out of that clay square and roll it on through a pasta machine. Later, smack it a while with a wooden spoon. Yup...pottery!

Admittedly the first 3:40 or so of this video is just watching clay getting formed, not that sciency or exciting. Then the furnace opens up, and they reach in with just gloves (at 4:30) to reload the kiln. Sheesh...

And finally, at 9:20, we get to see the finished products...so pretty.

High-tech cement for extreme tasks - TUM-chair for construction materials

Concrete is almost always a solid choice.

(Sorry...)

The video seems to use the terms concrete and cement fairly interchangeably. I know they're not the same (cement being a component of concrete), but I'll admit to making the same mistake myself quite frequently.

This might be a good video to show somewhere along the way with the cement hockey pucks lab as they use various additives with cement to change the properties of the cement pretty drastically, making the cement easier to pump, slower setting, better able to retain water, or more resistant to pressure or CO2.

By the way, in the fluidity test, does the reddish additive (shown being measured at 3:49) really say Magic Compound on the paper (see 3:55)?

Thursday, July 4, 2013

Material Marvels with Ainissa Ramirez - Shape Memory Alloys

Those Lego figures stuck to the boards are ones I'm trying to collect. I have the wolfman, but I need all the rest. Wonder is Ainissa would send them my way.

Ainissa actually does a great job explaining why the memory alloy switches back and forth as temperature is raised - at least at a low level of explanation - at 2:20, explaining that the material switches from monoclinic to cubic crystal structures.

Space Shuttle Thermal Tile Demonstration

Yeah, but twenty-two hundred degrees for hours...but is that celsius or fahrenheit?

Wussies...

The move at 1:20 sums up my thoughts. Check the very shaky hands, man.

Railroad thermite welding

There are just no words.

I mean, really, this video has no words what so ever.

What it does have is...at 0:15 a thermite mixture placed on a heated form...at 0:23 an ignitor lit and placed in the mixture...at 0:28 a controlled hell breaking loose, peaking at about 0:35...molten iron leaking into the form at 0:45 (I think)...an awesome sound at 0:48...or maybe molten iron leaking at 0:50...I have no idea what the yellow thing does at 2:05...still glowing iron being cleaned up at 2:45...and big grinding at 3:30.

And that's what thermite is used for.

Concrete: A slightly tongue-in-cheek look

That's a big piece of sewer pipe. It's kind of weird that it's in sharper focus than is the rest of the frame, though.

The Engineer Guy makes some concrete - apparently from quickcrete - and then waits for it to set while his sample cures.

At 1:45 he says that concrete doesn't really dry and explains what's really happening. Then, though, at 2:05 he says he's going to wait for the concrete to dry. Sheesh...

Copper: The Miracle Metal

The sound is all out of whack here, but if you hang around for the outtakes at the end of the concrete video, you can see why they had to use such extensive overdubbing.

I do dig the smooth slide to the right at 1:33.

Copper's five properties are - in case you missed them...

- inert to water

- easily shaped

- plays friendly with other metals

- 100% recyclable

- easily shaped

- conducts electricity

- tolerates heat

But I might like things to be a little more linear when he's listing five things.

How a lead-acid battery works

Batteries are just so freakin' cool.

I had no idea the specific chemistry inside a lead-acid battery. Lead plus lead oxide making lead sulfate in each case...brilliant.

The comment at 3:00 - "with most engineered objects, there are going to be trade-offs, giving away the characteristics you want to gain others you must have" - is a marvelous summary of much of our design challenges.

Light bulb filament

This video, made to accompany an article on Wired magazine's website, absolutely blows me away. First off, the ease with which The Engineer Guy takes off the glass envelope of the light bulb at 0:45 is stunning. Can anybody recreate that with a pipe cutter? I've been trying for a couple of weeks with absolutely no luck.

At 0:58 then, the video does a great zoom in on the supercoiled tungsten filament and shows the original 20-inch filament coiled then coiled again.

The next part of the video - from 1:30 through 2:30 - explores the ductility of tungsten and the processes necessary to make it ductile. The six steps - at 2:00 - absolutely blow my mind. That anybody could ever figure those steps out is amazing.

And the video closes with explaining the need for the glass envelope and the gas within.

Great, great video!

Tempered Glass Breakage

I'm always impressed with the surprising strength of tempered glass - and the willingness of people on YouTube to do stupid things without gloves.

When we discuss the strength of tempered glass in our summer workshops, occasionally a camper will ask why we would use such glass as a cutting board. If a nick on the edge (or especially the corner) leads to spectacular failure, why would be take a knife and go at the surface of the glass?

Because this video. That's why.

Extreme Boating

Randall Munroe - of xkcd fame - continues to explore scientifically interesting if perhaps thoroughly unpractical questions at his what if blog.

A recent post asked - and answered - "What would it be like to navigate a rowboat through a lake of mercury? What about bromine? Liquid gallium? Liquid tungsten? Liquid nitrogen? Liquid helium?"

The first and last questions - mercury and helium - get by far the lengthiest explanations with the general conclusions being that mercury would be barely feasible and helium would be deadly but at least musically so.

Along the way, I learned a lot about why rowing on bromine would be horribly unpleasant, the melting point of tungsten, and about the reactivity of liquid nitrogen.

Thanks, Randall.

A recent post asked - and answered - "What would it be like to navigate a rowboat through a lake of mercury? What about bromine? Liquid gallium? Liquid tungsten? Liquid nitrogen? Liquid helium?"

The first and last questions - mercury and helium - get by far the lengthiest explanations with the general conclusions being that mercury would be barely feasible and helium would be deadly but at least musically so.

Along the way, I learned a lot about why rowing on bromine would be horribly unpleasant, the melting point of tungsten, and about the reactivity of liquid nitrogen.

Thanks, Randall.

XY Wire Drawing Machine Video 1

The consistent tone and repetitive sounds make this a perfect video to doze off to.

The idea is simple enough. A spool of wire is fed through a lubricator then through a draw plate. The wire is then rewound and the process repeated.

I recommend starting the video at about 2:20 so that you can watch the full process from beginning to end. Pay particular attention to the speed of the first spool as compared to the successive speeds - especially the final one.

Subscribe to:

Comments (Atom)